|

|

|

|

|

CERAMIC

PTC THERMISTORS : GENERAL HEATING APPLICATIONS

PH SERIES PTC HEATING THERMISTORS |

|

|

In most heating applications. PTC thermistors do not require independent

controlling devices such as thermostat, temperature limiter, and thermal fuse. The device safety is introduced by the thermistor's self-regulating effect, a property unique to the thermistor. In heating applications, ceramic PTC thermistors offer long term stability while providing unmatched safety against overheating. Unlike the traditional resistive heating elements, these ceramic thermistors do not consume atmospheric oxygen during the heating phase. |

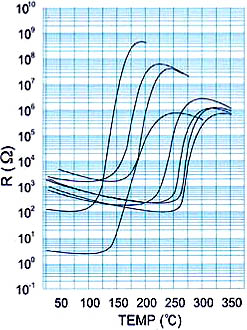

| When ceramic PTC thermistors are used in heating applications, they are processed so that the operation temperature range is close to the TSW. In order to achieve optimum heating power, these thermistors are operated at the rated voltage in the low-resistance portion of the R/T curve. Most ceramic PTC thermistors can be processed to exhibit a broad switching temperature range in a variety of dimensions. |

|

|||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

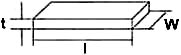

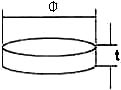

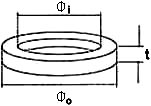

| Dimensional Rating : | ||

|

|

|

| I=3-40mm ; w=2-30mm ; t>1.5mm |

|

2

|

| Electrical and Thermal Rating : | ||

|

|

|

|

|

|

|

|

|